-

16 2018-08

Evaluating Pharmaceutical Container Closure Systems

The use of qualitative and quantitative methods can help packaging professionals determine the presence of extractables and leachables.

David E. Albert, NAMSA (Northwood, OH)

The United States Pharmacopeia (USP) and FDA have been and continue to be the driving force behind the safety evaluation of materials and container closure systems in the United States. An important step in such evaluations is characterizing the materials and the chemicals that can migrate or extract from container closure system components to the drug product. Figure 1 shows the various types of chemicals that can migrate from polymeric materials1. Such basic information is critical to understanding the biological safety and suitability of a container. A number of tests can be used to establish initial qualification of the container closure system, and a quality control plan can help ensure compatibility and safety. -

16 2018-08

Single-Use (SU) Container Closure Integrity (CCI)

Regulatory & Industry Requirements

SSB Position Statement on SU-CCI

Quality Risk Management, Process Validation and QC

Supplier bag chamber leak test and Integrity Testing

Pre Use Leak Testing for Flexboy®

Conclusions -

16 2018-08

Method Development for Container Closure Integrity Evaluation via Headspace Gas Ingress by Using Frequency Modulation Spectroscopy

-

15 2018-08

PACKAGE INTEGRITY EVALUATION—STERILE PRODUCTS

-

16 2018-08

Role of packaging material on Pharmaceutical product stability

AgendaGeneral Overview ¾What is packaging? ¾Importance of packaging ¾Functions of packaging ¾Material characteristics

Choosing the Appropriate Primary Pack Suitable polymer/ Blister Packs Containers & Closures

Testing of materials QC test QC Plus Pack integrity

Regulatory US, EU, Pharmacopoeial

Case studies

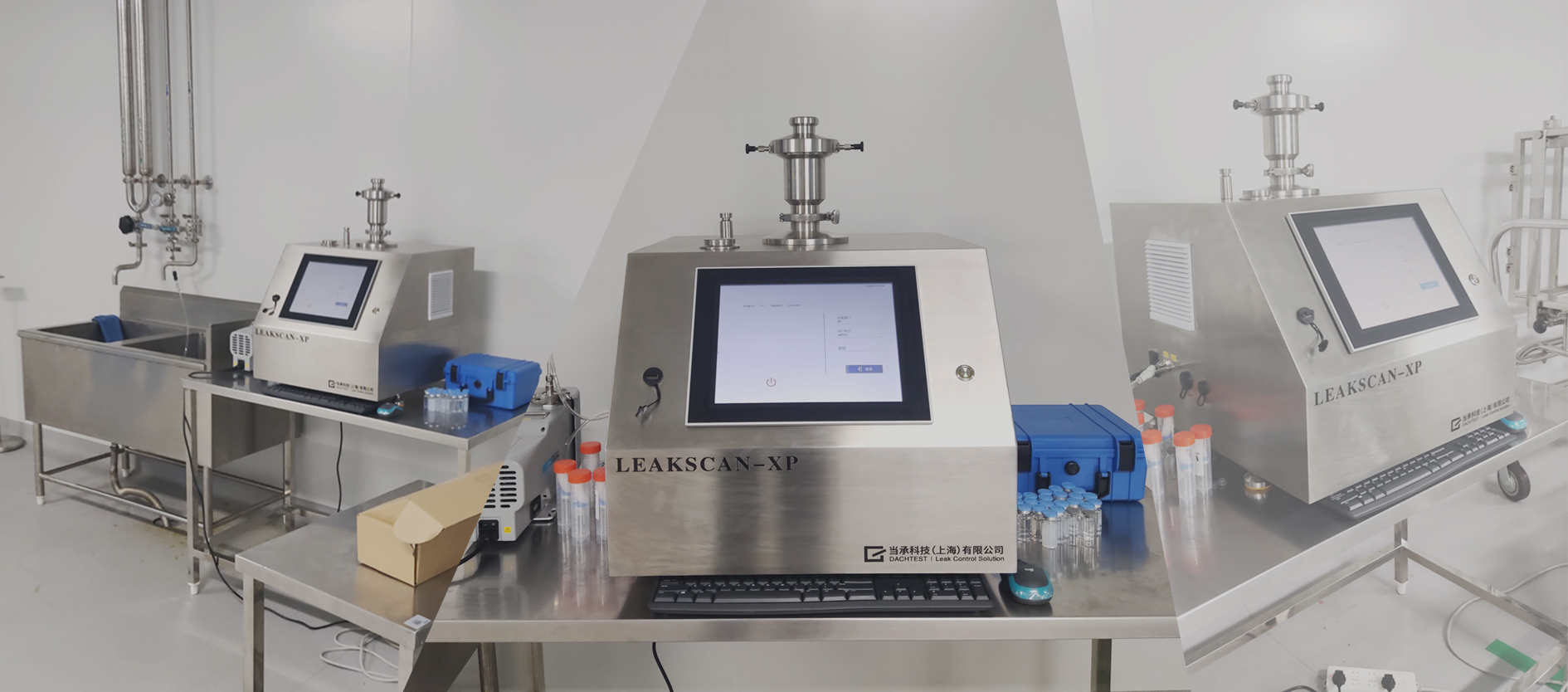

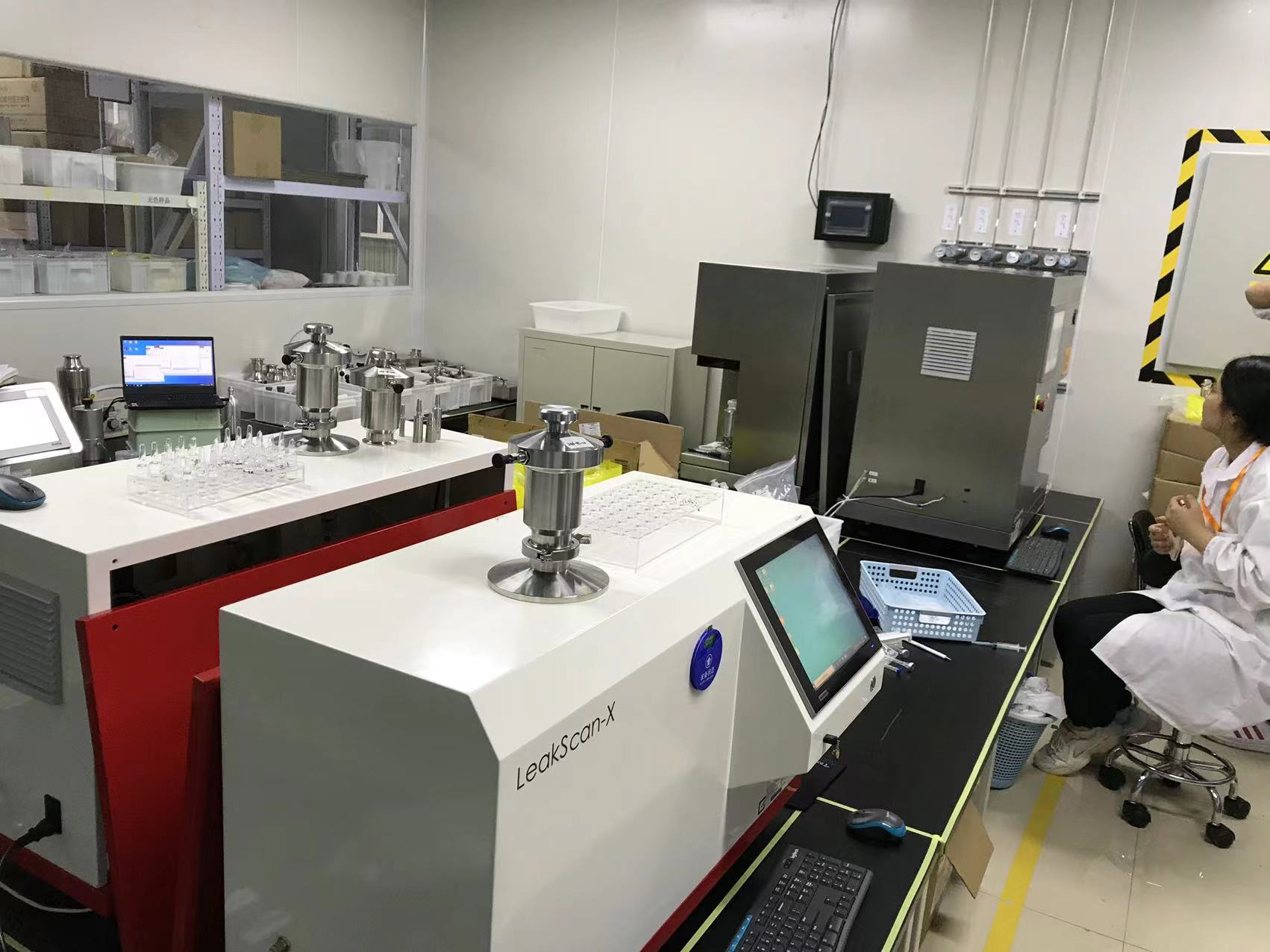

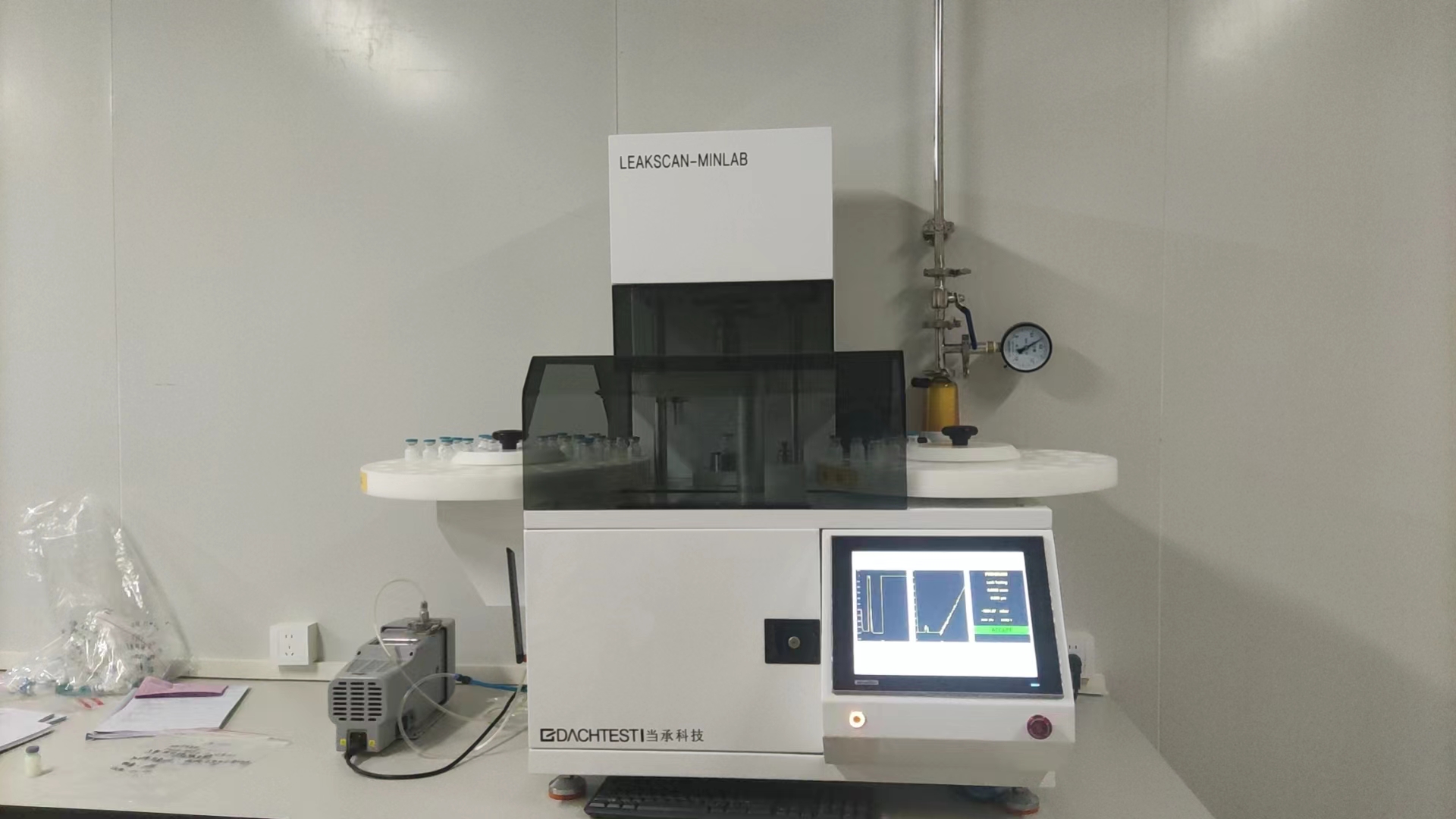

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

当承科技