-

10 2024-12

DESIGN, CONTROL, AND MONITORINGOFSINGLE-USE SYSTEMS FOR INTEGRITY ASSURANCE

DESIGN, CONTROL, AND MONITORINGOFSINGLE-USE SYSTEMS FOR INTEGRITY ASSURANCE

The risk management plan contains four key elements – Business, Product, Operator & Environment, and Integrity. The latter involves a Quality by Design (QbD) approach including a road map of the product life cycle to identify the quality attributes that are important for the achievement of system integrity. The guide highlights the importance of a shared responsibility by the supplier and end(user in the evaluation and implementation of the plan, and gives detailed recommendations on issues relevant to system integrity such as process validation, packaging, QC testing, installation, training, etc. -

10 2024-12

Impact of Container Closure System on Freeze Drying Process.

Impact of Container Closure System on Freeze Drying Process.

Parenterally delivered drugs have gained popularity over the last decade because of their ability to act immediately, flexibility to be administered in a controlled manner and superior compliance as compared to oral medications.1 In addition, freeze dried parenterals also offer significantly improved storage stability for liquid formulations that otherwise do not offer an acceptable storage stability. -

10 2024-12

Container closure integrity testing with High Voltage Leak Detection

Container closure integrity testing with High Voltage Leak Detection

There are various methods that can be used for Container Closure Integrity Testing(CCIT). Each method has its pros and cons. The choice of the CCIT-method depends on various factors such

as the material of the primary packaging and product properties.

High Voltage Leak Detection(HVLD) is an effective method. The sensitivity of the method is quite high but its is unclear

whether it can detect all the hole sizes that may entails a risk for microbial contamination. -

10 2024-12

Experience with Artificial Leaks and Dye Ingress Container Closure Integrity Testing (CCIT)

Experience with Artificial Leaks and Dye Ingress Container Closure Integrity Testing (CCIT)

Critical leak

•Void, gap, crack, hole, porosity or breach in a container closure system allowing the passage of microorganisms

•Main factor that affects critical leak size is whether or not the micro-leak is filled with liquid: microorganisms penetrate a liquid filled defect by motility or pressure differentials -

10 2024-12

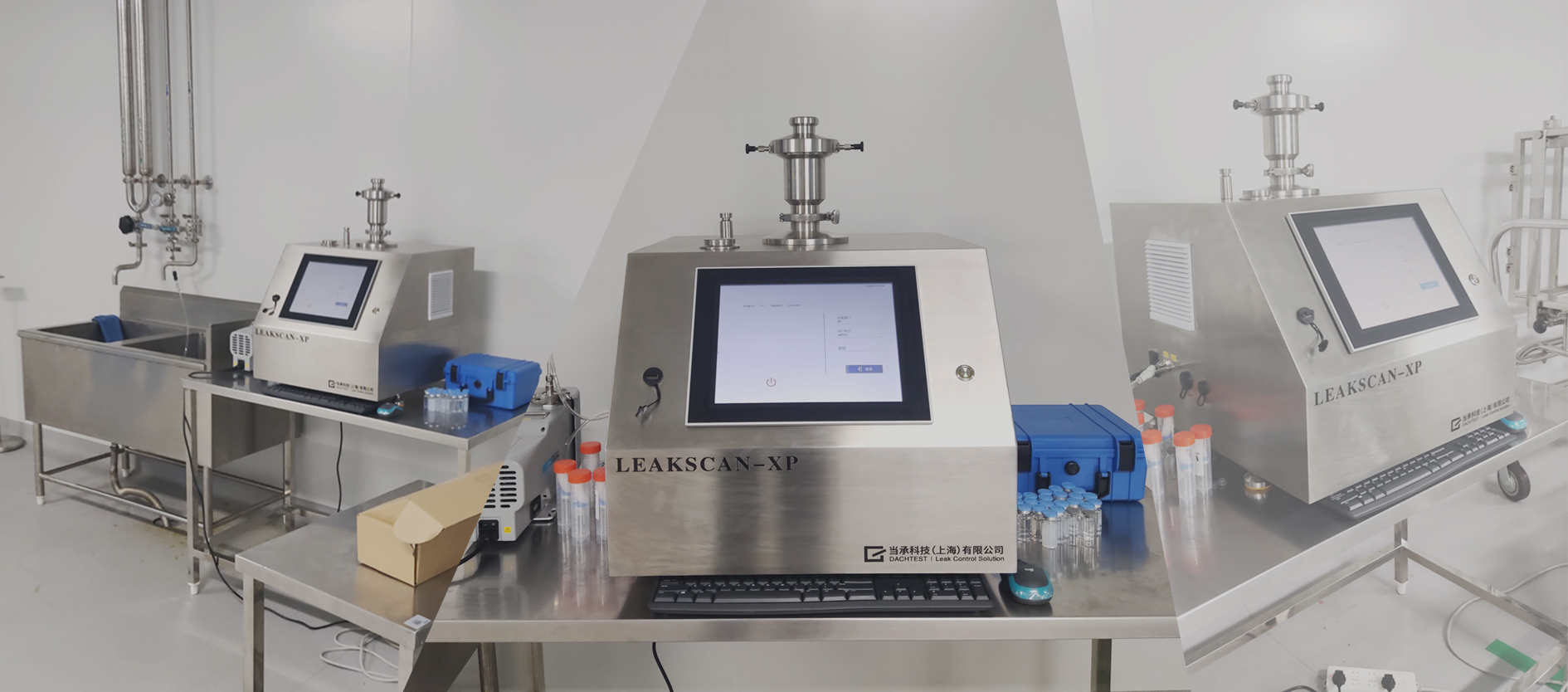

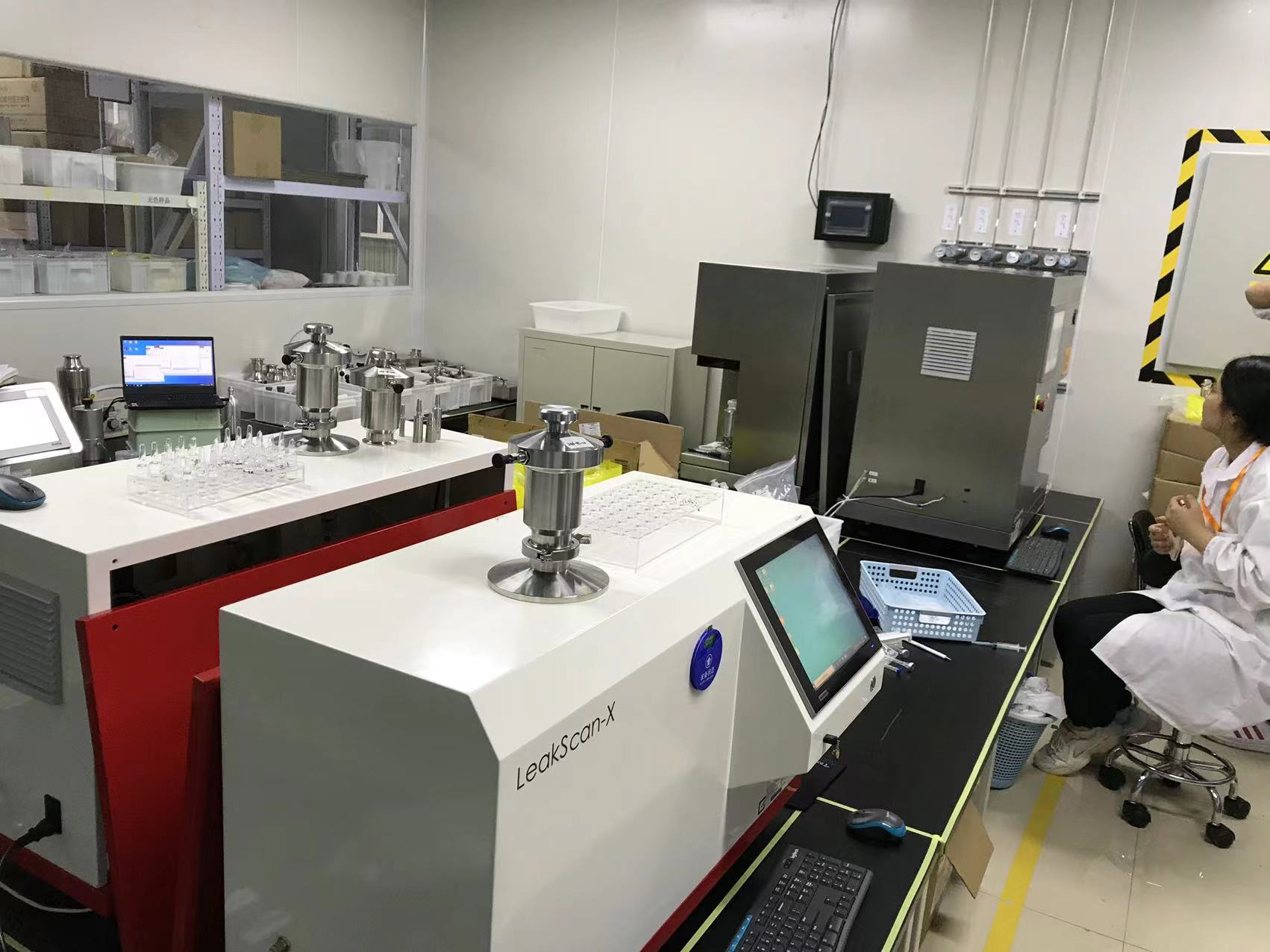

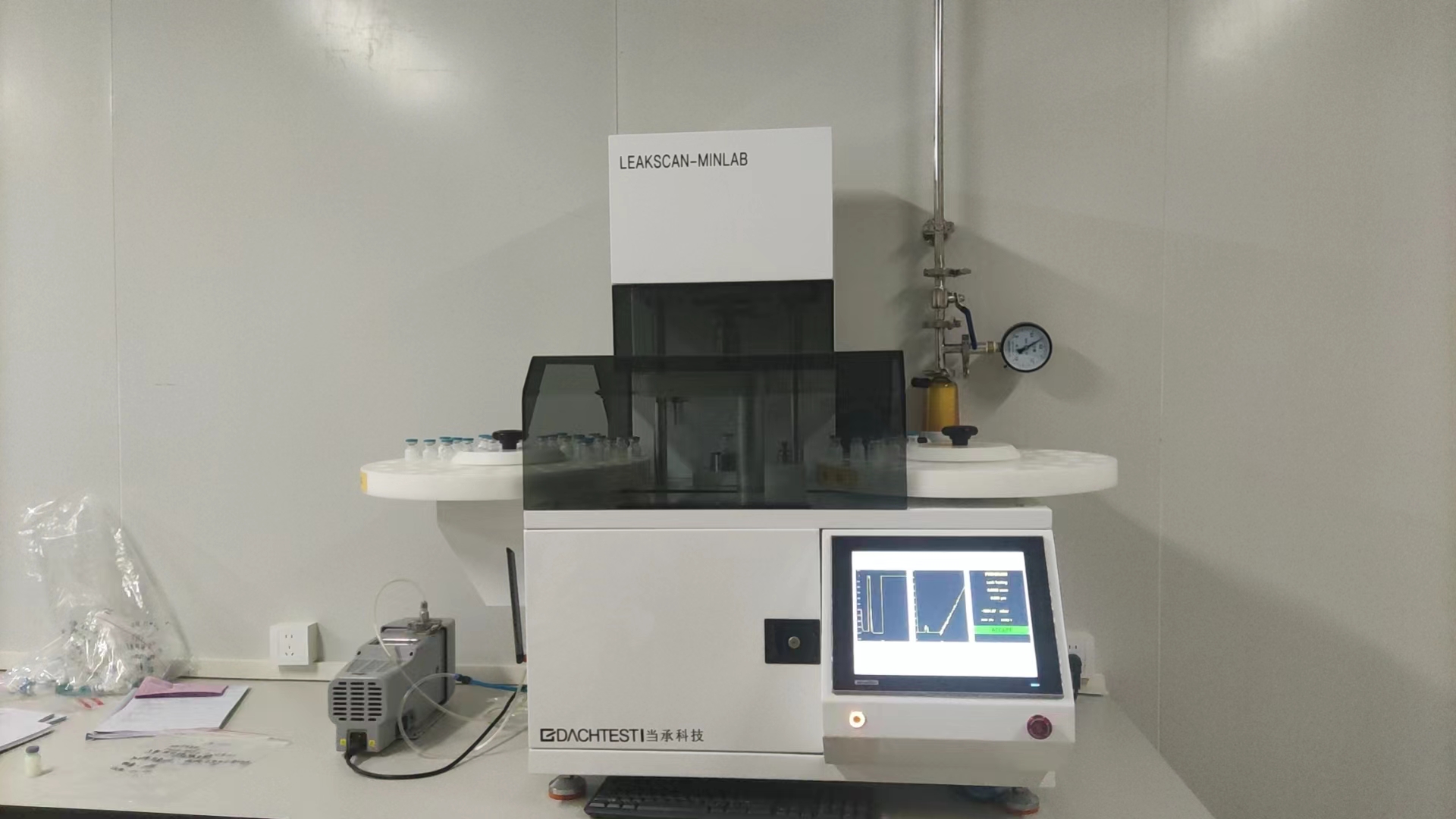

Using Helium Leak Detection CCI Testing to Inform Container Closure System Design

Using Helium Leak Detection CCI Testing to Inform Container Closure System Design

Overview of Helium Leak Detection (HeLD)

Method development for syringes

Fixture design

Helium charging

Applications of Helium Leak Detection

Determination of inherent package integrity

Evaluation of syringe system and sub-system design

Assessment of container closure robustness

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

当承科技