包装容器密封完整性检测参考文献

Product and Package Stability Studies: The Application of FDA Guidance

来源:

|

作者:pmo90dc87

|

发布时间 :2018-08-15

|

2435 次浏览:

|

分享到:

The United States Food and Drug Administration provides guidance on physical tests to employ to demonstrate that packaging maintains the sterility of products throughout their shelf life. This article discusses what this means in practice for medical device manufacturers.

M. TUrNEr,

MEDicAl ENGiNEEriNG

TEchNoloGiES lTD,

FolkESToNE, Uk

M. TUrNEr,

MEDicAl ENGiNEEriNG

TEchNoloGiES lTD,

FolkESToNE, Uk

微信公众号

服务热线:

联系我们

地址:上海市宝山区呼兰路799号智汇园4号楼(一楼)413单元

电话:021-56633066/56633166

手机:18500186197

邮箱:jackge@dchtest.com

网址:https://www.dchtest.com/

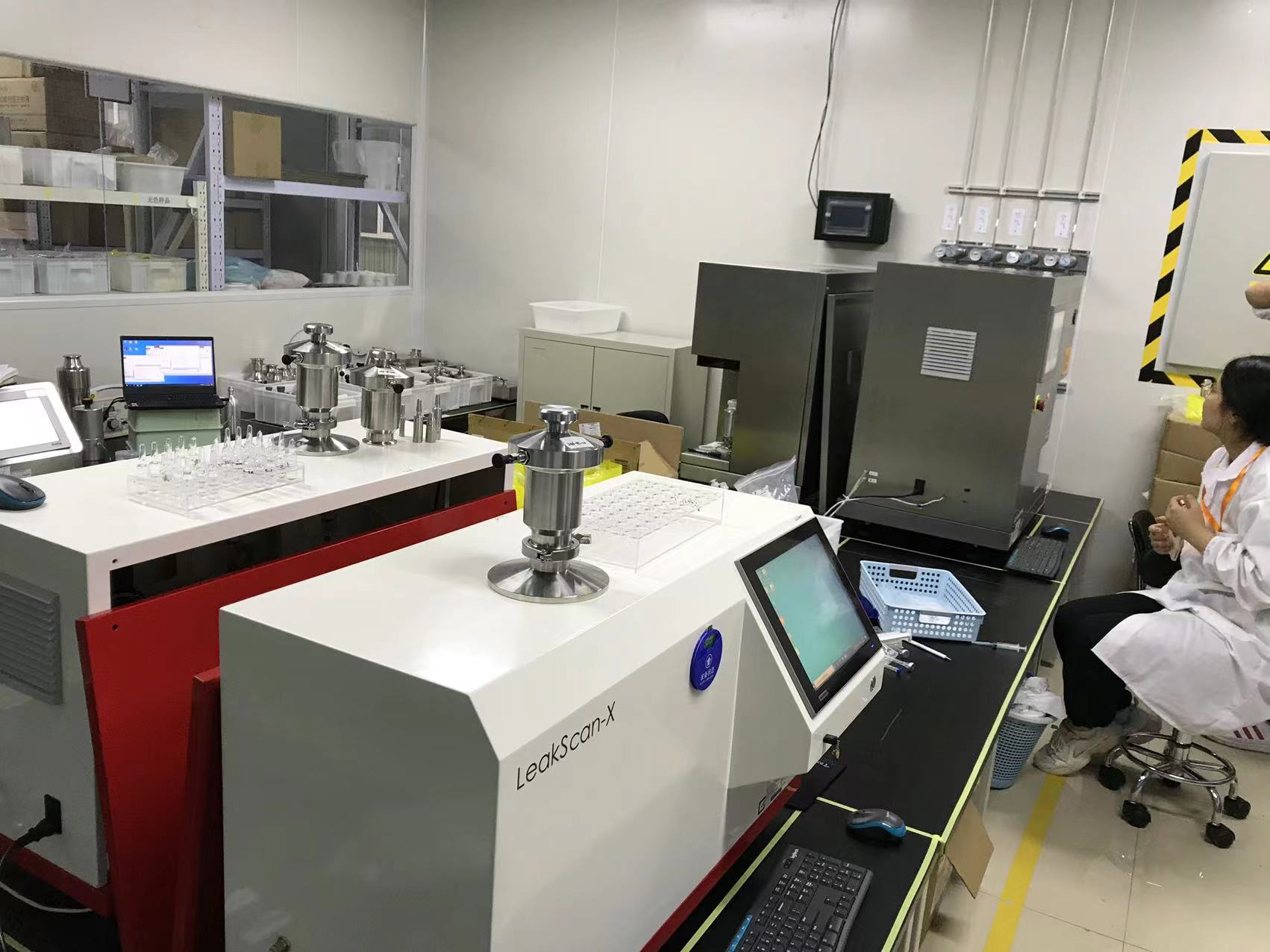

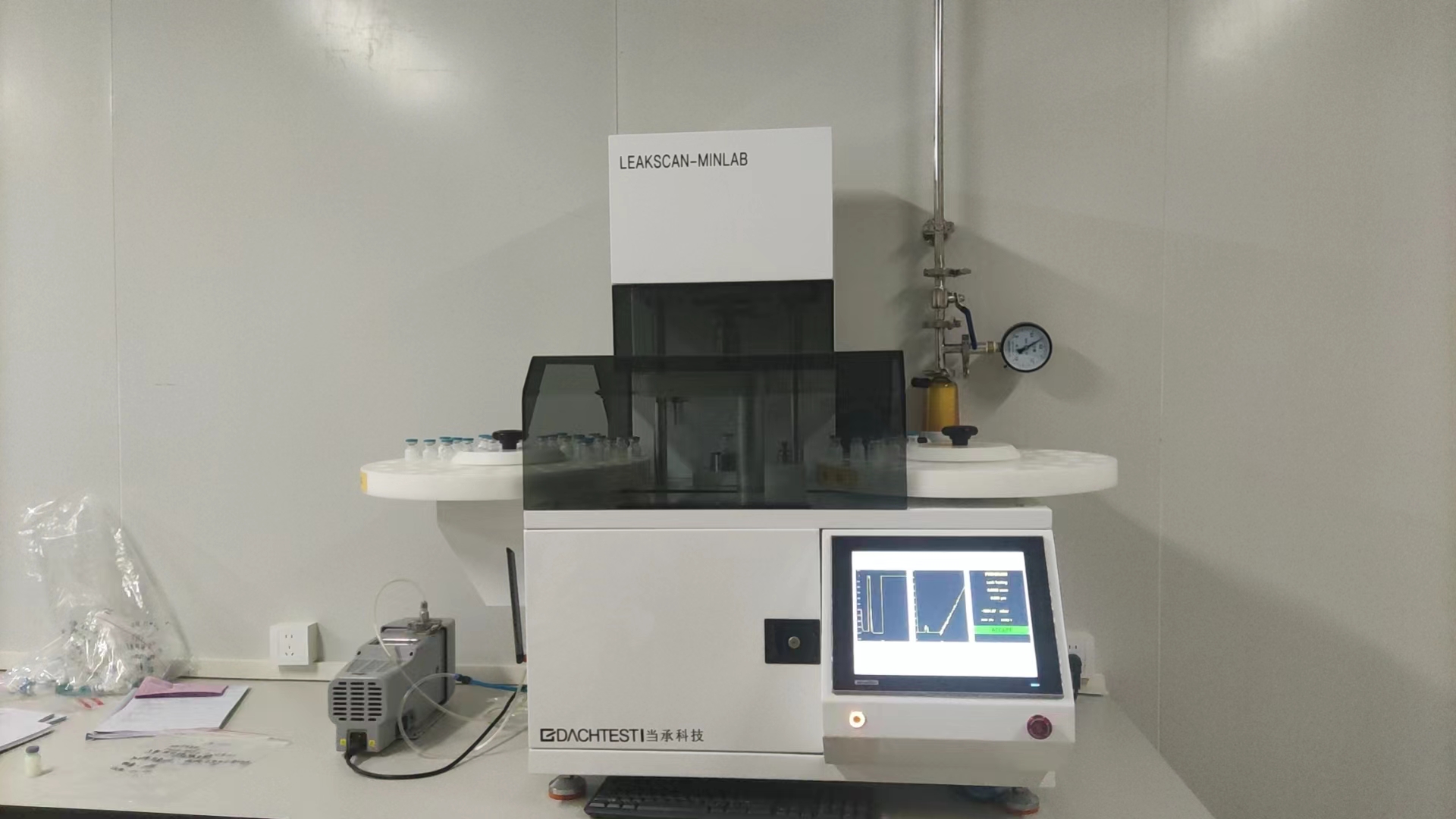

设备展示

021-56633066

产品中心

当承科技