Understanding Container Closure Integrity Testing

来源:

|

作者:pmo90dc87

|

发布时间 :2018-08-16

|

1916 次浏览:

|

分享到:

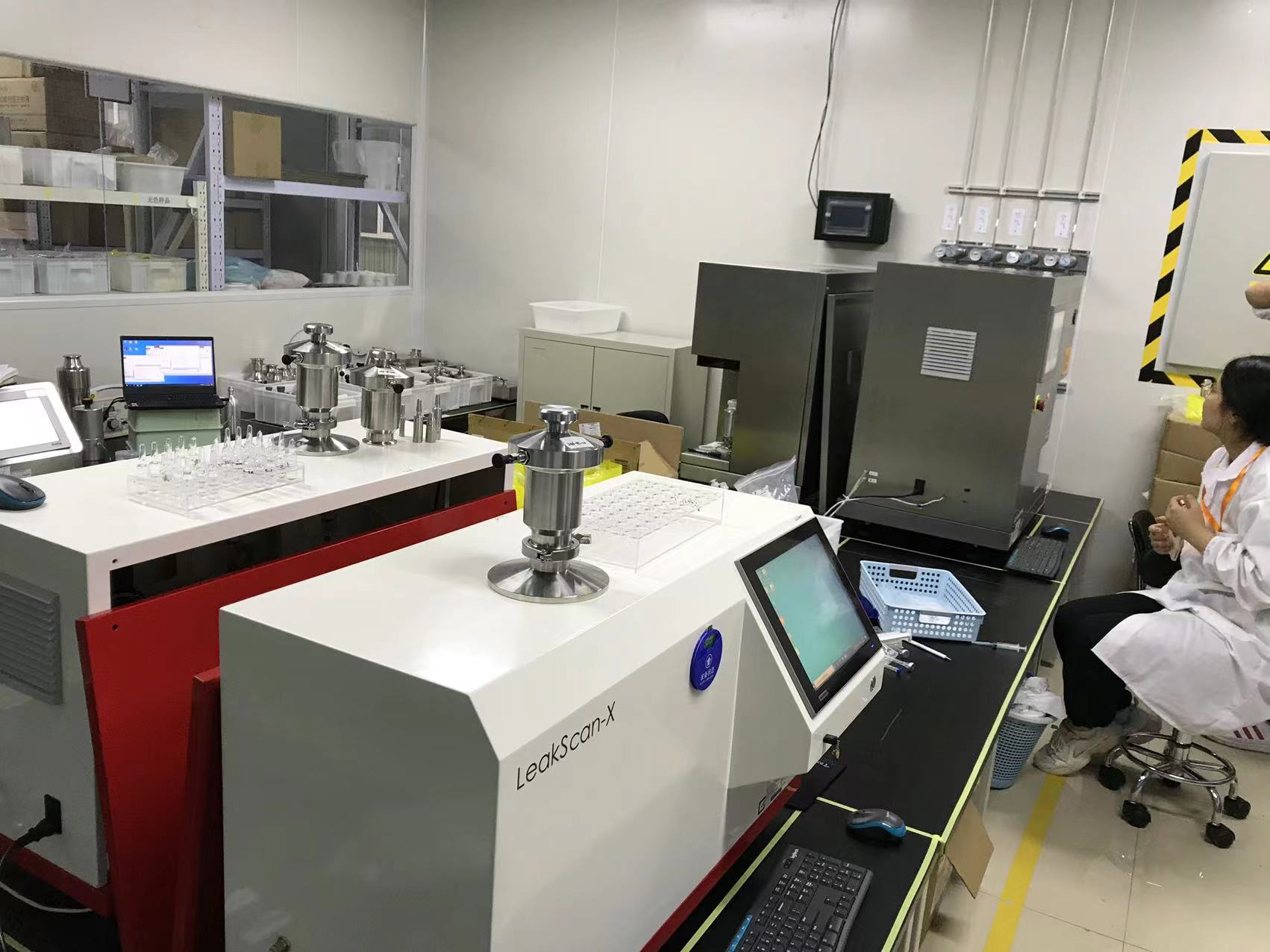

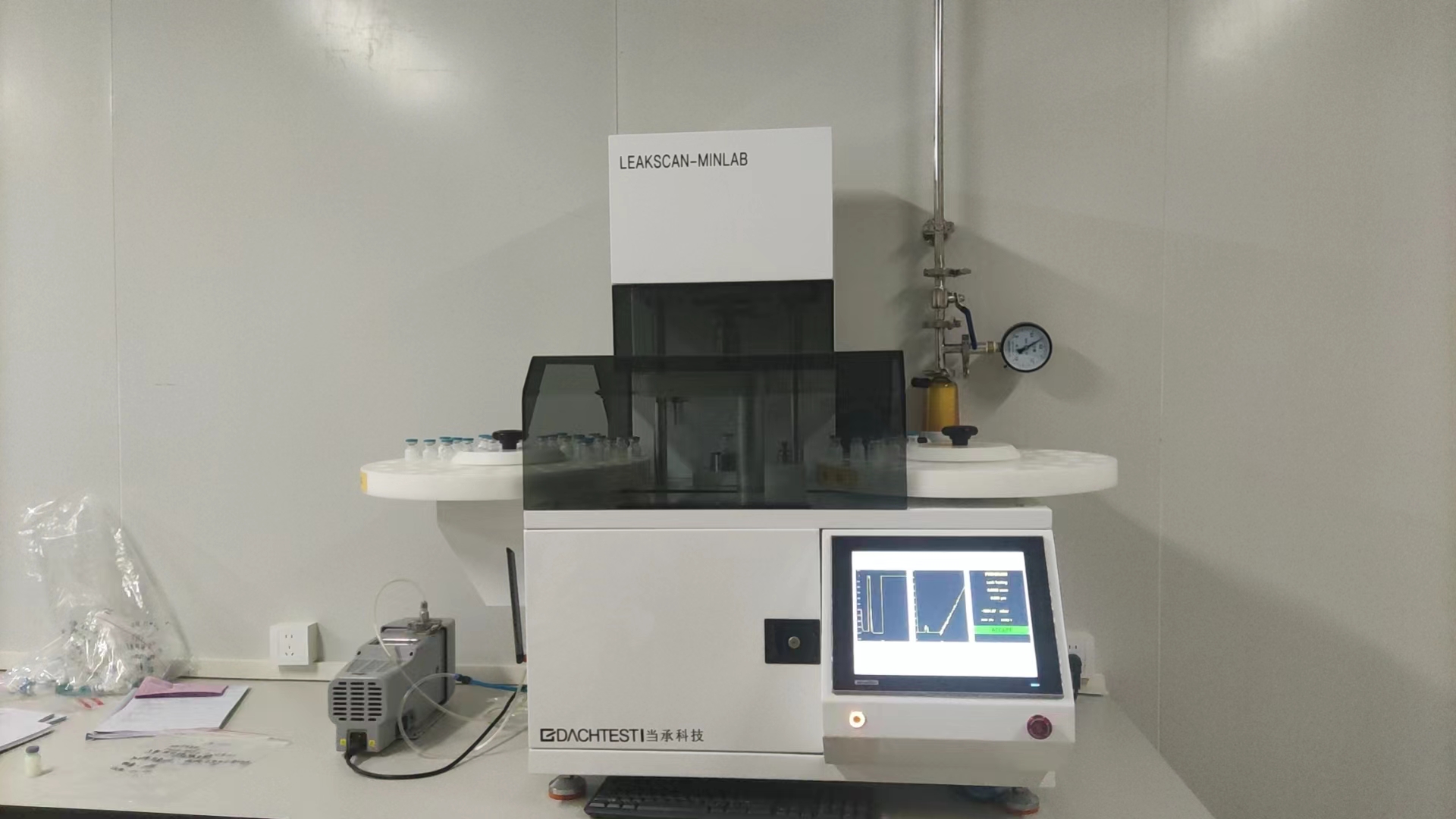

Understanding container closure integrity systems, reviewing past observations, and following the regulations and guidance documents are excellent ways to establish a compliant container closure integrity assay. This article describes recent changes to the United States Pharmacopeia (USP) , guidance documents, regulatory observations, common container closure methods, and provides recommendations on developing and validating a compliant container closure integrity test.

Overview

Container Closure Integrity Testing (CCIT) is an assay that evaluates the adequacy of container closure systems to maintain a sterile barrier against potential contaminants. Contaminants that could potentially cross a container closure barrier include microorganisms, reactive gases, and other substances (USP <1207>). Container closure systems should maintain the sterility and product quality of sterile final pharmaceutical, biological, and vaccine products throughout their shelf-life (Ewan, S. et al., 2015). Container closure systems consist of primary packaging components and secondary packaging components (USP <1207>). Primary packaging components are those components that come into direct contact with the product, such as a glass vial or syringe.

While, secondary packaging components are those components that are vital to ensure correct package assembly, such as aluminum caps over stoppers (USP <1207>).

There are many guidance documents and regulations that govern container closure integrity systems. The following list of guidance documents and regulations is not an all-inclusive list, but these resources provide valuable information.